A zen koan?

No, a common problem, and one that came up today whilst fixing a circular table.

In a world of homogenous materials, which can be cut in pretty much any way with impunity, it is easy to forget that homogenous materials are really quite modern. In the past the basic materials used for building and making things were composite and directional. Wood is a fibrous material that changes shape irregularly with changing humidiity. Wrought iron is also fibrous, and has to be worked with due respect for the direction of those fibres. And stone has fracture lines and grain.

Forgetting this leads to some interesting structural failures, especially self destruction. This post explores one such type of failure.

The mahogany circular drop leaf table in question had a split in one of the leaves. Looking at it more closely, it was clear that the glue line between two boards had opened up. Looking through the crack with the light behind revealed a dowel in the centre and two steel pins and each end.

I pulled the two pieces apart, and tried to fit them together again. There was a gap of 2 millimetres, no matter how hard I pushed.

And here’s what had happened. The dowel was holding the two pieces apart, a dowel that had clearly been inserted when the table was made.

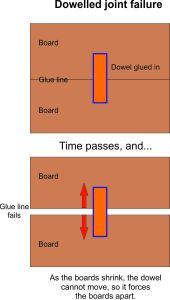

This is a common problem in gluing joints. In this case, the grain of the dowel is at 90 degrees to the grain of the wood. As the wood of the table loses moisture and shrinks, the dowel stays the same length. If the end of the dowel is glued in place, the glue line in the table is literally forced open by the dowel as the table shrinks.

This is a common problem in gluing joints. In this case, the grain of the dowel is at 90 degrees to the grain of the wood. As the wood of the table loses moisture and shrinks, the dowel stays the same length. If the end of the dowel is glued in place, the glue line in the table is literally forced open by the dowel as the table shrinks.

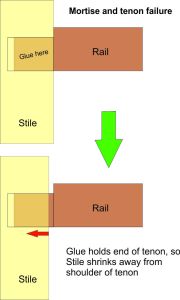

The same thing happens with a spline joint or a biscuit joint in solid wood. The glued, un-shrinking spline or biscuit forces the shrinking wood apart. It’s even worse in a mortise and tenon joint. By gluing the end of the tenon in the mortise, the mortised piece shrinks back from the shoulders of the tenon and the joint becomes structurally weaker, as the shoulders no longer support it – so it will probably rack.

In each case the joint self-destructs.

What is the solution? Well the explanation for the problem is the failure to understand what the glue and the spline or dowel or biscuit is for. In the case of an edge joint, like this table leaf, the glue is to glue the boards together. The dowel, spline or biscuit is to locate the boards accurately when they are being glued. Indeed the traditional way of edge joining boards is to use no spline or dowel, but a very well fitting ‘rubbed glue’ joint which doesn’t even need to be clamped up! So don’t glue the dowel at all.

What is the solution? Well the explanation for the problem is the failure to understand what the glue and the spline or dowel or biscuit is for. In the case of an edge joint, like this table leaf, the glue is to glue the boards together. The dowel, spline or biscuit is to locate the boards accurately when they are being glued. Indeed the traditional way of edge joining boards is to use no spline or dowel, but a very well fitting ‘rubbed glue’ joint which doesn’t even need to be clamped up! So don’t glue the dowel at all.

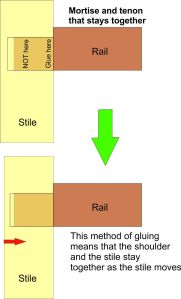

In a mortise and tenon joint, the glue is to hold the joint in place. The joint should be made to be strong enough to perform its duty without any glue – indeed many mortise and tenon joints are wedged or pegged, not glued. So the glue can simply be applied to the area adjacent to the shoulder of the tenon and just inside the mortise. Then when the mortised piece shrinks, it will shrink towards to shoulder, not away from it.

In a mortise and tenon joint, the glue is to hold the joint in place. The joint should be made to be strong enough to perform its duty without any glue – indeed many mortise and tenon joints are wedged or pegged, not glued. So the glue can simply be applied to the area adjacent to the shoulder of the tenon and just inside the mortise. Then when the mortised piece shrinks, it will shrink towards to shoulder, not away from it.

Basic principle – Wood shrinks and expands a lot across the grain, but very little along it. Join the two orientations together in a rigid relationship at your peril.

Leave a comment

Comments feed for this article